Synchro Engineering Innovates in Partnership with Niagara-based Manufacturers

Synchro Engineering from Niagara Falls, ON, Canada responded to the call to action by our Government for manufacturers to become innovative in producing Personal Protective Equipment (PPE) and other health related supplies. Accepting a supply chain partnership with their client, Clean Works, Synchro worked through the Research and Development phase of converting Clean Works' food sanitizing equipment, winner of a 2019 Innovation Award (International Association for Food Safety) into a mini sanitizer unit for PPE. Synchro’s supplier partnership involved the design and manufacturing of the control system for the Healthcare Mini.

The Team at Synchro, were on board to assist their client on this redesign that came with a very aggressive timeline initiative. This critical pivot, during the COVID health emergency, occurred when Synchro was trying to navigate the state of emergency orders and understand the impacts it was going to have on their business and customers. Three priorities needed to be addressed and followed through by Synchro’s team: safety, rapid growth and continued service for all their established local customers.

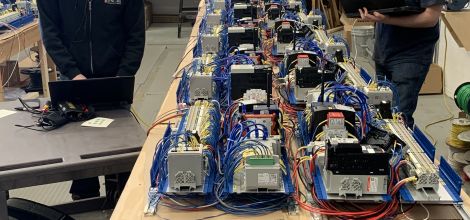

With a quick turnaround and safety protocols in place, Synchro immediately implemented online collaboration with employees, suppliers and Clean Works. For the quantity of control panels forecasted to be produced, they leased more space from their landlord, Signature Signs.

Resulting from a surge in supporting their Food and Beverage manufactures needs and other customers who increased their own productions requirements to keep shelves stocked, Synchro’s dedicated team swelled from 15 employees to over 23. Their manufacturing footprint quadrupled, which permitted them to produce Clean Flow’s Healthcare Mini equipment control panel designs within six weeks verses what would have been normally accomplished over a 1 year period.

Health Canada approved the Healthcare Mini equipment, which kills 99.9% virus pathogens using ultraviolet light, hydrogen peroxide and ozone. Each device can sanitize up to 800 N95 masks per hour and can also sanitize face shields and goggles. The adaptation was made in April 2020 and was soon serving over 65 health-care institutions across Canada.

Following the Clean Works Healthcare Mini sanitizer project, Synchro was able to adjust back this summer to service all their well-established clients in food & beverage processing, other manufacturing businesses, and energy & mining sector. Most recently they have expanded their portfolio to include Printed Circuit Board design and programming.

Back to articles

Back to articles